Bảo hộ lao động

- Bao bì - Đóng gói

- Bảo hộ lao động

- Bơm công nghiệp

- Bùlon ốc vít

- Cân các loại

- Cao su, Nhựa các loại

- Chuyển giao công nghệ

- Cửa - kính các loại

- Dầu khí - Thiết bị

- Dây chuyền sản xuất

- Dệt may - Thiết bị

- Dầu mỡ công nghiệp

- Dịch vụ - Thi công

- Điện công nghiệp

- Điện gia dụng

- Điện Lạnh

- Đóng tàu Thiết bị

- Đúc chính xác Thiết bị

- Dụng cụ cầm tay

- Dụng cụ cắt gọt

- Dụng cụ điện

- Dụng cụ đo

- Gỗ - Trang thiết bị

- Hàn cắt - Thiết bị

- Hóa chất-Trang thiết bị

- Kệ công nghiệp

- Khí nén - Thiết bị

- Khuôn mẫu - Phụ tùng

- Lọc công nghiệp

- Máy công cụ - Phụ tùng

- Mỏ - Trang thiết bị

- Mô tơ - Hộp số

- Môi trường - Thiết bị

- Nâng hạ - Trang thiết bị

- Nội - Ngoại thất - văn phòng

- Nồi hơi - Trang thiết bị

- Nông nghiệp - Thiết bị

- Nước-Vật tư thiết bị

- Phốt cơ khí

- Sắt, thép, inox các loại

- Thí nghiệm-Trang thiết bị

- Thiết bị chiếu sáng

- Thiết bị chống sét

- Thiết bị an ninh

- Thiết bị công nghiệp

- Thiết bị công trình

- Thiết bị điện

- Thiết bị giáo dục

- Thiết bị khác

- Thiết bị làm sạch

- Thiết bị sơn - Sơn

- Thiết bị nhà bếp

- Thiết bị nhiệt

- Thiêt bị PCCC

- Thiết bị truyền động

- Thiết bị văn phòng

- Thiết bị viễn thông

- Thủy lực-Thiết bị

- Thủy sản - Trang thiết bị

- Tự động hoá

- Van - Co các loại

- Vật liệu mài mòn

- Vật liệu xây dựng

- Vòng bi - Bạc đạn

- Xe hơi - Phụ tùng

- Xe máy - Phụ tùng

- Xe tải - phụ tùng

- Y khoa - Trang thiết bị

Sản phẩm VIP cùng nhóm

DANH MỤC SẢN PHẨM

» Bảo hộ lao động

Sunflower Covering Pellet Maker

LIÊN HỆ MUA HÀNG

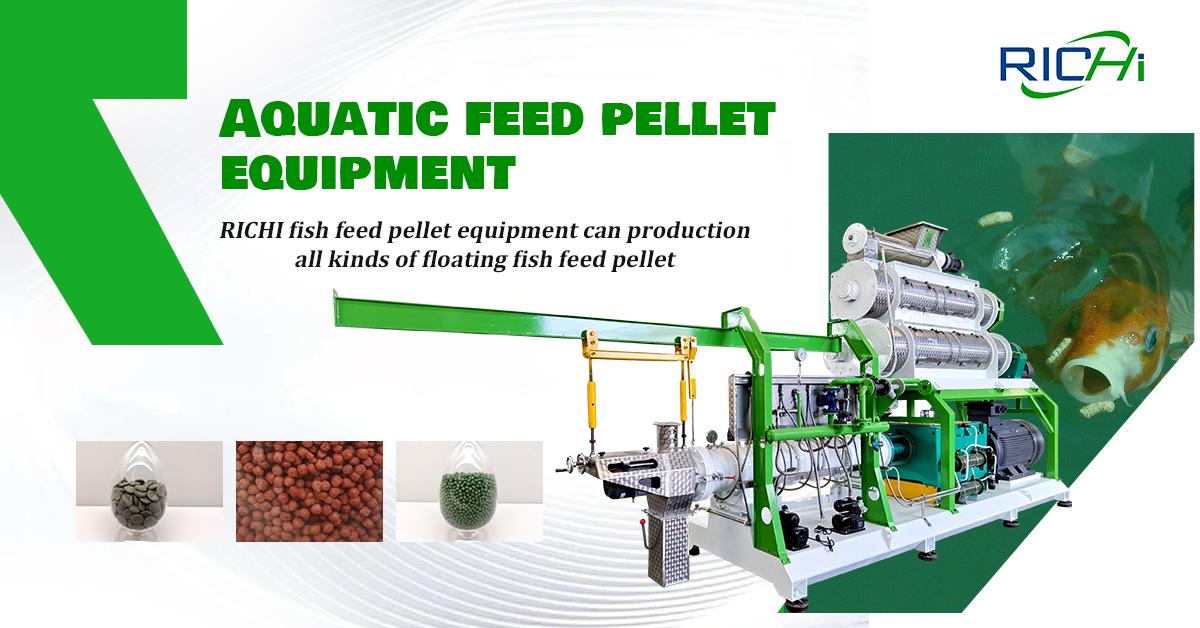

A sunflower shell pellet device is a biomass handling device particularly made to press sunflower seed shells into compact and energy-dense pellets. These makers are vital consequently agricultural waste into a sustainable, clean-burning gas resource, advertising using renewable resource while lowering waste and environmental pollution.

What Are Sunflower Shells?

Sunflower shells, additionally referred to as sunflower seed husks, are the external protective layer of sunflower seeds. They are a byproduct produced throughout sunflower seed handling, specifically after oil extraction. In regions with significant sunflower farming and oil production-- such as Ukraine, Russia, Argentina, and parts of China and the USA-- sunflower shells are created in big quantities. While they were as soon as thought about waste, sunflower coverings are now identified as a high-potential biofuel due to their make-up and energy value.

They have a high lignin material, which serves as an all-natural binder during pellet development, and their calorific worth approaches that of softwood. In addition, sunflower coverings normally have reduced wetness content, which reduces the demand for pre-drying and makes them a perfect basic material for pelletizing. Sunflower Shell Pellet Machine

Just How a Sunflower Covering Pellet Machine Functions

A sunflower shell pellet equipment operates by applying high pressure and temperature level to press loosened, light-weight coverings right into tough, cylindrical pellets. The procedure normally starts by feeding the shells right into the equipment via a receptacle. Inside the equipment, a roller and die system puts in pressure on the raw product, requiring it via tiny die openings to form pellets. The heat generated by rubbing throughout compression softens the lignin in the coverings, allowing the pellets to hold their form without added binders.

After extrusion, the hot pellets are cut to the preferred size and afterwards transferred to a cooling section, where their temperature level is minimized and their structure stabilized. The final product is a high-density, long lasting gas pellet that is easier to keep, manage, and transportation than raw biomass.

Advantages of Sunflower Covering Pellet Machines

Making use of a sunflower covering pellet device uses numerous financial and ecological advantages. First and foremost, it enables sunflower processing centers to turn a waste item into a useful resource. This waste-to-energy conversion reduces disposal prices and produces a brand-new revenue stream.

The resulting pellets are clean-burning and carbon-neutral, making them a suitable choice to coal, gas, or oil for home heating and commercial power. In addition, pellets are easier to transport and keep because of their consistent size and decreased quantity compared to loose shells. This aids firms minimize logistics prices and enhance fuel effectiveness.

From a technological viewpoint, these devices are developed for constant procedure, using high productivity with marginal hands-on intervention. Modern makers typically include PLC control systems that allow operators to change specifications like feed price, pellet diameter, and operating stress, making sure consistent pellet quality.

Applications of Sunflower Covering Pellets

Sunflower shell pellets are made use of in different fields. In commercial setups, they function as boiler fuel for factories, greenhouses, and power plants. Their regular energy outcome and reduced discharges make them ideal for biomass power generation.

In residential contexts, they are frequently utilized in pellet ranges and boilers for home heating. Sunflower shell pellets are also employed in the agricultural field, either as bedding for animals or, in many cases, as an additive in natural fertilizer formulas after combustion.

Because of their high calorific value, reduced ash material, and superb burning properties, sunflower covering pellets are getting appeal in worldwide biomass markets, specifically in nations with stringent ecological regulations and high need for eco-friendly fuel.

Trick Demands for Pelletizing Sunflower Shells

To produce premium pellets, the raw sunflower shells need to meet particular problems. The optimal dampness web content of the raw material is between 10% and 15%. If the moisture is too high, a drying out procedure utilizing a rotary drum clothes dryer or belt dryer might be necessary.

The size of the shells should be little adequate to go through the die openings of the device. If required, a hammer mill or crusher is used to break down larger fragments. Contaminations such as stones, steels, or plastics need to be gotten rid of before refining to prevent damaging the pellet maker.

Kinds Of Pellet Machines for Sunflower Coverings

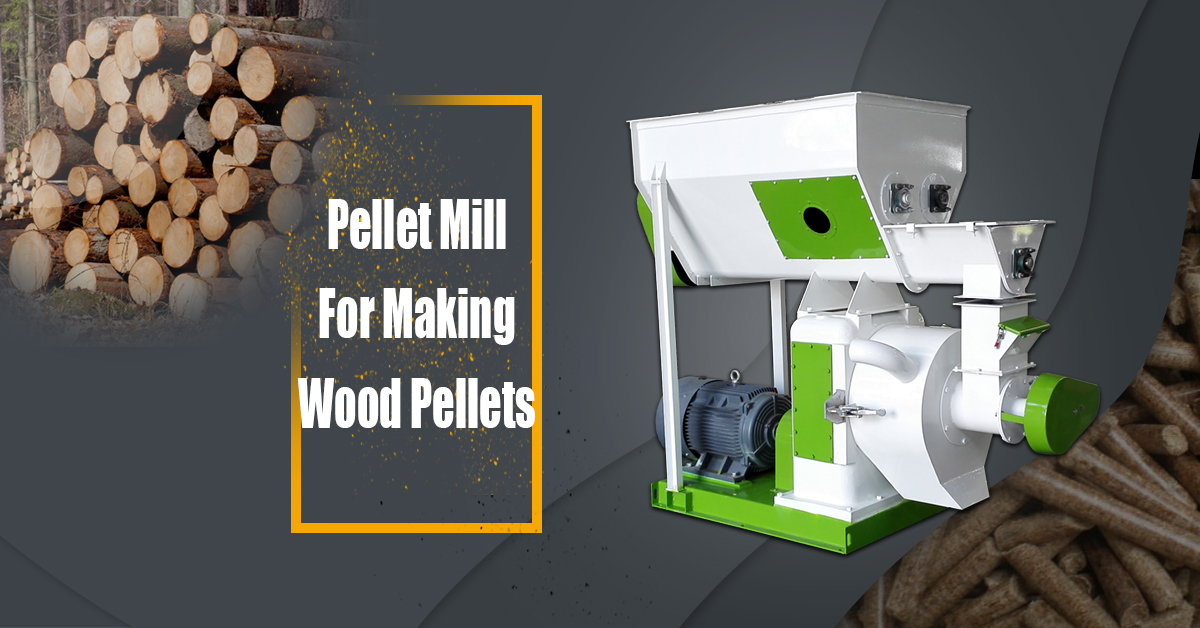

There are typically two sorts of pellet machines utilized for processing sunflower coverings: ring pass away and level die pellet machines. Ring pass away equipments are created for massive industrial production. They are durable, energy-efficient, and efficient in creating approximately 20 lots of pellets per hour. These makers are suitable for industrial pellet plants.

Flat die devices are smaller sized, easier, and usually utilized in tiny ranches or home setups. While they have lower ability, they are easier to run and preserve. The selection between the two depends on the customer's production range and operational spending plan.

Production Line Arrangement

A full sunflower shell pellet assembly line normally includes a number of handling actions and corresponding tools. These consist of a basic material feeding system, crushing devices (if required), drying system, the core pelletizing machine, a pellet cooler, and a packaging system. Additional components like dirt collection agencies and control closets might likewise be consisted of, particularly in industrial-scale procedures.

Each component plays a crucial duty in ensuring efficient manufacturing. For instance, the drying system guarantees that the raw product has the appropriate moisture degree, while the cooler supports the pellets prior to they are packaged and stored.

Picking a Trusted Supplier Pellet plant

Choosing a reputable supplier is vital when purchasing a sunflower shell pellet equipment. Firms like RICHI Equipment have over 30 years of experience in biomass pellet equipment manufacturing and offer complete complete pellet manufacturing remedies.

A reputable producer offers not only top quality equipment but additionally technological assistance, installation support, extra components, and after-sales services. In addition, many leading suppliers offer personalization choices to tailor devices requirements to fulfill particular basic materials, production targets, and ecological problems.

Obstacles in Pelletizing Sunflower Shells

While sunflower shells are a superb biomass source, there are some difficulties to consider. As a result of their difficult texture, they can trigger enhanced wear on maker components like rollers and dies. This requires using high-grade, wear-resistant products in machine building.

Sunflower shells likewise generate even more dust throughout processing compared to some other biomass products. Efficient dirt collection systems need to be installed to guarantee operator security and keep clean working conditions.

Additionally, the ash material of sunflower shell pellets is slightly more than that of wood pellets. This might call for more frequent cleaning of stoves or boilers, especially in domestic applications.

Market Trends and Need

The global need for biomass pellets is growing steadily, driven by environment modification plans, rising fossil fuel rates, and public recognition of renewable energy. In this context, sunflower shell pellets are emerging as a competitive biofuel, especially in Eastern Europe, Central Asia, and parts of Latin America where sunflower farming prevails.

Because of this, the marketplace for sunflower shell pellet makers is expanding. Businesses associated with sunflower oil production, farming waste management, and biomass energy are increasingly wanting to purchase pelletizing technology to maximize this fad.

Conclusion

The sunflower shell pellet machine is an essential device in the renewable resource sector. By transforming farming waste into valuable biomass gas, it helps reduce ecological influence, advertise lasting advancement, and boost financial returns for manufacturers. Whether for commercial usage or property home heating, sunflower covering pellets are a sensible and environment-friendly energy source, and the makers that create them are ending up being significantly important in the international bioenergy landscape.

If you remain in the biomass market, purchasing a sunflower covering pellet device is a calculated action that aligns with future power patterns and sustainable production objectives.

Sản phẩm doanh nghiệp: Henan RICHI Machinery Co., Ltd.

Henan RICHI Machinery Co., Ltd.

15238494867

Henan

richipelletizer@gmail.com

https://richipelletizer.com/

-

Găng tay chống cắt HG-7-L Atom, găng tay Trusco 293-4019,

[Mã: G-14587-58] [xem: 1723]

[Nhãn hiệu: Atom - Xuất xứ: Nhật]

[Nơi bán: Hồ Chí Minh]

2021-06-25 17:55:30] Mua hàngCÔNG TY TNHH CÔNG NGHỆ & THƯƠNG MẠI HÀ SƠN

0906 663 719 ( MR. LUÂN) -039 279 3301 (MS. DIỆU)

nguyenluan319@gmail.com

Số 69/9, Nguyễn Gia Trí, Q. Bình Thạnh, TPHCM -

Đại lý tập vĩnh tiến,tiến phát!

[Mã: G-27304-90] [xem: 1827]

[Nhãn hiệu: tiến phát - Xuất xứ: vn]

[Nơi bán: Hồ Chí Minh]

2018-05-10 14:30:06] 3,000 Mua hàng

Sản phẩm cùng nhà cung cấp

Sản phẩm xem nhiều

Nhà cung cấp chuyên nghiệp

Tin tuyển dụng mới

» Xem tất cả-

Cáp mạng UTP/FTP Cat5e Cat6 Altek Kabel

Cáp mạng UTP/FTP Cat5e Cat6 Altek Kabel * Thông tin sản phẩm: Cáp mạng...

-

Cáp báo cháy - Chống cháy - Chống nhiễu Altek Kabel

Cáp báo cháy - Chống cháy - Chống nhiễu Altek Kabel Thương Hiệu Altek...

-

Nhân viên kinh doanh xe nâng hàng

MÔ TẢ: - Tư vấn, giới thiệu các sản phẩm xe nâng. - Quản lý và phát triển...

-

Tuyển NV Kinh doanh thiết bị công nghiệp, tự động hóa

• Địa điểm làm việc: TP.HCM • Số lượng tuyển: 02 người • Hình thức...

15238494867

15238494867

![Sửa Máy Lạnh tại TPHCM [Trung Nam] Uy Tín – Chuyên Nghiệp – Tận Tâm](https://chodansinh.net/assets/upload/chodansinh/res/product/58690/sua-may-lanh-5zlwsKbinc.jpg)